What Are the Latest Innovations in Underwear Manufacturing Techniques?

Article

1. The Evolution of Underwear Manufacturing: From Traditional Techniques to Innovations

2. Significant Advances in Fabric Technology for Enhanced Comfort and Support

3. The Role of Automation and Robotics in Streamlining Underwear Production

4. Sustainable Practices: Eco-friendly Materials and Manufacturing Methods in Underwear Production

5. Customized Products: Personalizing Underwear Manufacturing to Meet Individual Needs

The Evolution of Underwear Manufacturing: From Traditional Techniques to Innovations

Underwear, a garment worn directly against the skin, has evolved significantly over the centuries. From its humble beginnings as a basic undergarment, underwear has become a highly sophisticated and technologically-driven product. This article explores the latest innovations in underwear manufacturing techniques that have revolutionized the industry, ensuring superior comfort, quality, and functionality.

Significant Advances in Fabric Technology for Enhanced Comfort and Support

Textile advancements have played a pivotal role in transforming underwear manufacturing. Traditionally, underwear was made from natural fibers such as cotton, silk, and linen. However, modern manufacturers utilize a wide range of increasingly innovative materials to enhance performance, comfort, and durability.

One such material is microfiber, a synthetic fabric known for its softness and breathability. This material effectively wicks away moisture from the body, keeping the wearer cool and dry. Additionally, microfiber is resistant to wrinkling, shrinking, and fading, making it an ideal choice for long-lasting underwear.

The incorporation of elastane or spandex fibers has revolutionized the underwear industry by providing exceptional stretch and recovery properties. This enables underwear to adapt to body movements, offering increased support and freedom of movement. Elastane also helps maintain the garment's shape, preventing sagging and deformities over time.

Another revolutionary fabric innovation is the introduction of moisture-wicking and antimicrobial properties. These advancements combat sweat, odor, and bacterial growth, providing a fresh and hygienic feel throughout the day. Materials treated with such properties are particularly ideal for active individuals and those living in hot and humid climates.

The Role of Automation and Robotics in Streamlining Underwear Production

Automation and robotics have dramatically impacted the manufacturing process of underwear, improving efficiency and precision. Traditional techniques involved tedious manual labor, but with the advent of technology, automation has revolutionized the industry.

Cutting, stitching, and assembling fabrics have traditionally been labor-intensive processes. However, with the introduction of computer-numerical-controlled (CNC) cutting machines, manufacturers can now precisely cut fabric layers with minimal waste. CNC cutting machines use digital patterns to cut through multiple layers of fabric simultaneously, reducing production time and costs.

Furthermore, robotics has significantly improved the assembly and sewing processes in underwear manufacturing. Automated sewing machines equipped with multiple needles and threads can stitch complex patterns quickly and efficiently, surpassing human capabilities. Robotic arms assist in various tasks like attaching elastics, attaching labels, and folding the finished products, further streamlining the production process.

Sustainable Practices: Eco-friendly Materials and Manufacturing Methods in Underwear Production

In recent years, there has been a growing emphasis on sustainability in the fashion industry, including the manufacturing of underwear. Manufacturers are increasingly adopting eco-friendly materials and employing sustainable production methods to minimize their environmental impact.

One prominent eco-friendly fabric used in underwear manufacturing is bamboo viscose. Bamboo is a highly renewable resource that requires fewer pesticides, water, and land compared to traditional cotton cultivation. Bamboo viscose is exceptionally soft, hypoallergenic, and boasts excellent moisture-wicking properties, making it an excellent choice for sustainable underwear.

Recycled materials, such as polyester derived from plastic bottles or nylon made from fishing nets, are also gaining popularity in the production of sustainable underwear. These materials help reduce waste by repurposing existing resources, preventing the accumulation of non-biodegradable materials in landfills and oceans.

Moreover, manufacturers are adopting greener manufacturing methods, such as waterless dyeing processes, reducing the consumption of water and harmful chemicals. Implementing energy-efficient machinery and utilizing renewable energy sources further contribute to sustainable practices.

Customized Products: Personalizing Underwear Manufacturing to Meet Individual Needs

Modern consumers seek customized products that cater to their specific preferences and needs. To meet this demand, manufacturers are embracing innovative technologies to offer personalized underwear.

One such innovation is the use of 3D body scanning technology. This allows manufacturers to create garments tailored to an individual's unique measurements, ensuring optimal fit and comfort. By scanning the body's dimensions, these technologies generate accurate patterns that minimize fitting issues, enhancing overall satisfaction.

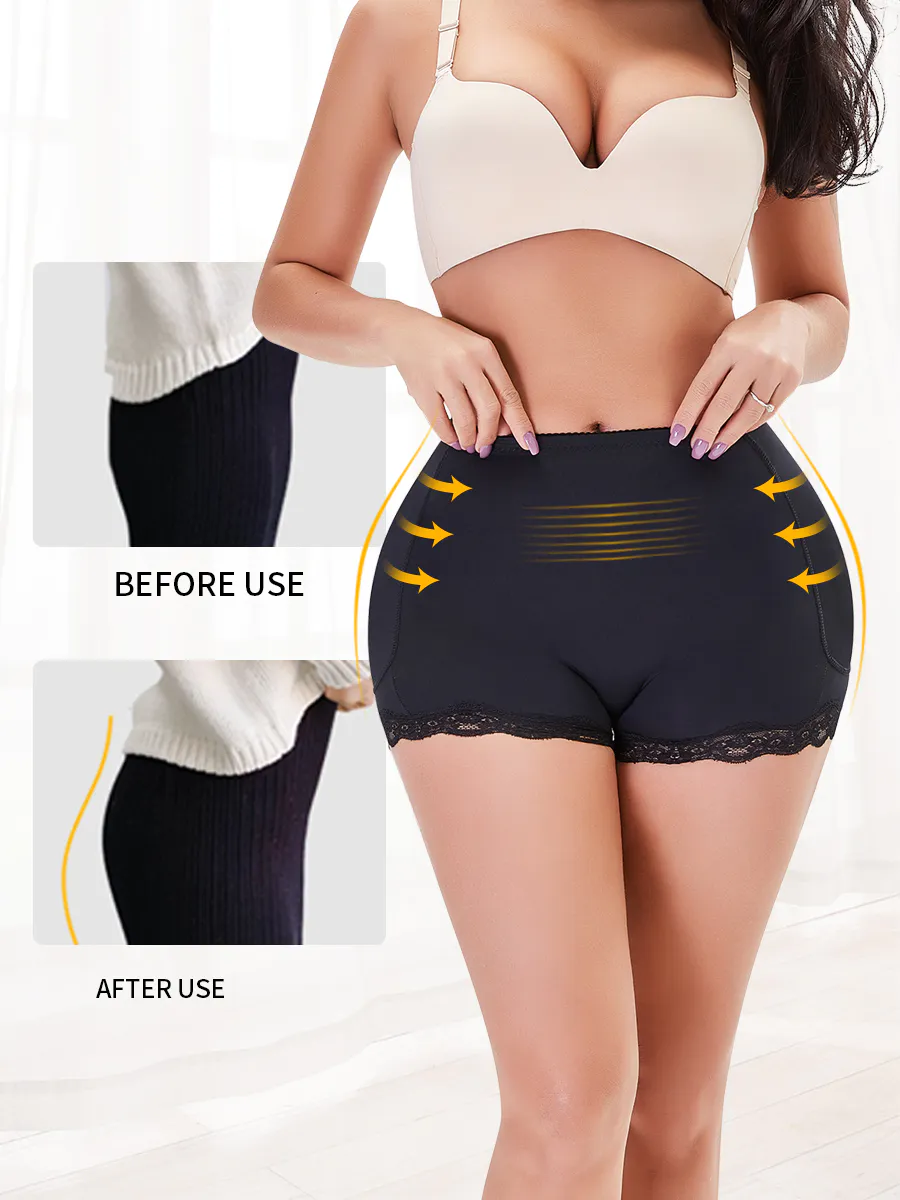

Additionally, advancements in seamless knitting machines enable the production of underwear with customized patterns, designs, and support zones. These machines can seamlessly integrate different fabric tensions and stitch counts within a single garment, providing targeted support and shaping where required.

Furthermore, advancements in digital printing technologies have enabled manufacturers to offer an extensive range of colors, patterns, and designs, with the ability to print directly onto fabric. This eliminates the traditional limitations posed by manual printing techniques, empowering consumers to express their individuality through their choice of underwear.

Conclusion

From fabric technology to automation, sustainability, and customization, the innovations in underwear manufacturing techniques have transformed the industry. The evolution from traditional methods to these cutting-edge technologies has enhanced comfort, improved sustainability, and catered to individual needs. As the demand for superior undergarments continues to grow, further innovations are expected, promising an even more exciting and personalized future for underwear manufacturing.

If you are looking for an effective and safe way to take care of net bra, then nursing Bras plus size swimwear manufacturers are the best bet.

Shantou Ladymate Apparel Co., Ltd. offers the best products, high-quality services and innovative technology.

LADYMATE is designed to enhance your savings in terms of cost, energy and efforts.If you are interested in our custom swimsuits plus size sexy bras products, please contact us soon.

The best way to determine the ideal strategy of lingerie suppliers is to continually test and refine your selling and marketing tactics.

There are different types of , mainly high waisted underwear plus size and sexy plus size swimsuits.