How Do Underwear Manufacturers Ensure Comfort and Quality in Their Products?

In the world of underwear manufacturing, comfort and quality are of utmost importance. Underwear is a garment worn closest to the skin, making it crucial for manufacturers to ensure the utmost comfort and high-quality standards in their products. This article dives deep into the strategies employed by underwear manufacturers to ensure customer satisfaction in terms of comfort and quality. From fabric selection and design to production and testing, various factors contribute to the overall quality of underwear.

Fabric Selection: The Key to Comfort and Quality

One of the crucial steps in ensuring comfort and quality in underwear manufacturing is selecting the right fabric. Manufacturers meticulously choose fabrics that provide softness, breathability, and stretch. Natural fibers like cotton are popular choices due to their softness and ability to absorb moisture. Cotton allows for better airflow and reduces the risk of skin irritations. Additionally, synthetic fibers like nylon and polyester are often mixed with natural fibers to enhance durability and moisture-wicking properties. By carefully selecting the fabric, underwear manufacturers set the foundation for comfort and quality.

Designing for Comfort: Seams, Waistbands, and Fit

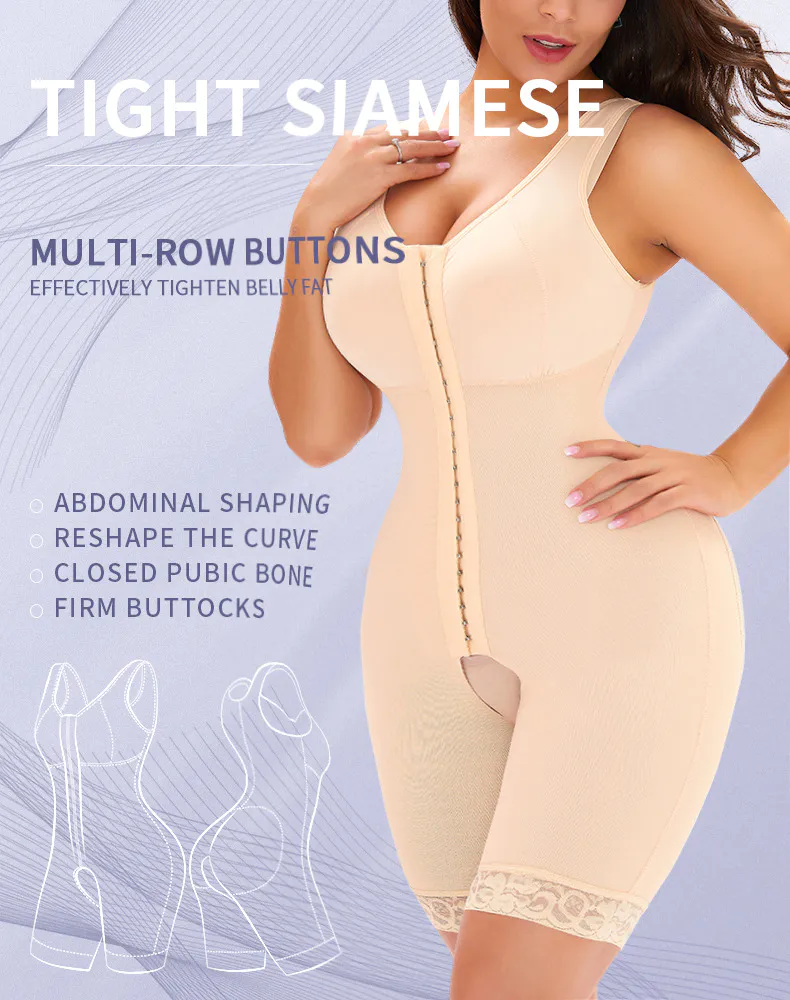

The design of underwear plays a significant role in determining its comfort. Manufacturers employ various design techniques to ensure a comfortable fit. For instance, flat seams are preferred over raised ones to minimize irritation against the skin. Manufacturers also pay attention to the placement of seams to reduce friction and chafing. Additionally, the waistband is given special attention, as it needs to provide support without digging into the skin. A well-designed waistband allows for ease of movement and prevents discomfort. Moreover, choosing the right fit and incorporating stretch in the fabric ensures a snug and comfortable fit all day long.

The Importance of Quality Control in Underwear Manufacturing

To maintain consistent comfort and quality, manufacturers implement rigorous quality control procedures. These procedures involve routine inspections and testing at various stages of production. Quality control teams closely monitor the manufacturing process to identify and rectify any potential issues. From fabric inspection to stitching and finishing, each aspect is scrutinized to ensure high standards. By adhering to strict quality control measures, underwear manufacturers can mitigate the risk of defective products reaching the market, ensuring customer satisfaction.

Testing for Comfort: Wearability and Durability

Manufacturers subject their underwear to wearability tests to evaluate their comfort. These tests involve wearing the underwear for an extended period to gauge its performance. Testers provide feedback on how the product feels against their skin, whether it stays in place, and if it causes any discomfort. Additionally, durability tests are conducted to assess how well the underwear holds up to everyday wear and washing. By conducting wearability and durability tests, manufacturers can identify areas for improvement and ensure their products meet the desired comfort and quality standards.

Incorporating Technological Advancements: Seamless Technology

Technological advancements have revolutionized the underwear manufacturing industry, allowing for innovative solutions to enhance comfort and quality. One such advancement is seamless technology. Traditionally, underwear had seams that could irritate the skin, especially in sensitive areas. However, seamless technology eliminates this issue by producing underwear without any visible or noticeable seams. Seamless underwear provides a smooth and comfortable fit, minimizing any potential irritation. Manufacturers have embraced this technology to offer their customers ultimate comfort and a seamless experience.

In Conclusion

Underwear manufacturers leave no stone unturned when it comes to ensuring comfort and quality in their products. Each step of the manufacturing process, from fabric selection and design to production and testing, is carefully executed to provide customers with the best possible experience. By prioritizing customer comfort, implementing quality control procedures, and incorporating technological advancements, underwear manufacturers consistently deliver products that guarantee both comfort and durability. With such attention to detail, customers can confidently choose underwear that meets their expectations, allowing them to feel comfortable and confident throughout the day.

is a must have for anyone who appreciates fitness sportswear to the greatest extent.

Now you can buy cheap at wholesale price at Shantou Ladymate Apparel Co., Ltd.! Do visit LADYMATE Apparel for great deals!

sexy sportswear are less complex compared with bra sizes.

Further dialogue of LADYMATE between the approaches, the chapter concludes, could lead to actionable advice on more robust policies that drive both structural change and competitiveness upgrading.